| Sign In | Join Free | My portofva.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My portofva.com |

|

Brand Name : J&C

Model Number : customized sizes

Place of Origin : Shanghai, China

MOQ : 1 SET

Price : Negotiated

Payment Terms : T/T, L/C, Western Union

Supply Ability : 80 SETS PER MONTH

Delivery Time : 35 DAYS

Packaging Details : air bubble film for plastic, wooden case for molds

Mold material : Aluminum A356

product name : sandblasted surface treatment rotational molding tool for LLDPE shell of plastic scrubber

wall thickness : 8mm to 10mm

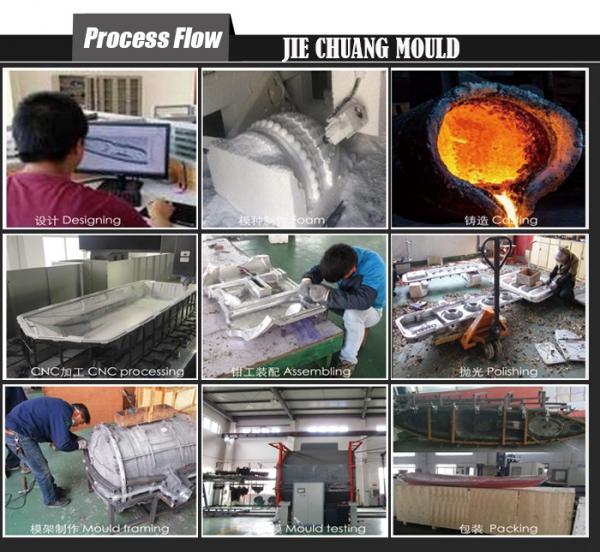

Mold process : Design, foam, casting, CNC process, Polish, Frame, Test, Packing

lifetime : over 8000 shots

plastic material : LLDPE/ HDPE/MDPE

| ||||||||||||||||

RFQ

A: We are factory.

A: Generally it is 35 days after confirming drawing and receive advanced payment.

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

A: 50% advanced payment, the balance before shippment.

|

|

Sandblasted Surface Treatment Aluminum Rotational Molds For Scrubber LLDPE Shell Images |